Test Data

Chemical Property Analysis Table

| Density | (15℃)g/cm3 | 0.8857 |

|---|---|---|

| Flash Point | (COC)℃ | 240 |

| Kinetic Viscosity | 40℃ mm2/s | 41.98 |

| 100℃ mm2/s | 7.222 | |

| Viscosity Index | 135 | |

| Pour Point | (℃) | -25 |

| Color | (ASTM): | L4.0 |

| Total Acid Value | (mgKOH/g) | 0.93 |

| Total Base Value | (mgKOH/g) | [*1] 60.2 |

| Chlorine Content | ppm | [*2] 10ppm or less |

| Falex Pin & Vee Block Test (Loading Gauge) |

(lb) | [*3] Incapable measurement (2500 or more) |

[ Japan Lubricating Oil Society ]

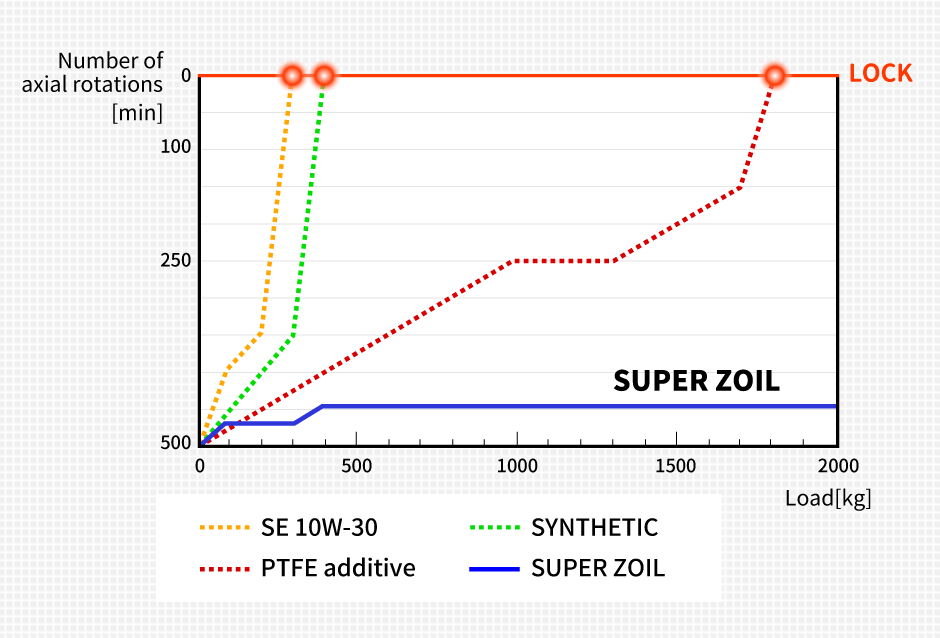

Pressure Resistance Test

Comparative Test

| Product Name | Unit | Auto Manufacturer's Recommended Oils |

Auto Manufacturer's Recommended Oils +SUPER ZOIL |

|---|---|---|---|

| Density | (15℃)g/cm3 | 0.8788 | 0.8811 |

| Flash Point | (COC)℃ | 236 | 228 |

| Apparent Low Temperature Viscosity | (-25℃) | 6310 | 6100 |

| Kinetic Viscosity | 40℃ mm2/s | 65.24 | 62.59 |

| 100℃ mm2/s | 10.15 | 9.789 | |

| Viscosity Index | 141 | 140 | |

| Pour Point | ℃ | -27.5 | -27.5 |

| Color | (ASTM) | 4 | 4 |

| Total Base Value | (mgKOH/g) | 6.99 | 11.4 |

| Soda Four-ball Type Test (Step Method) |

Load Carrying Capacity | 0.35 | 0.7 |

| Mpa | |||

| Wear Scar Diameter | 1.25 | 0.65 | |

| mm | |||

| Coefficient of Kinetic Friction in Pendulum Style Friction Test | 0.107 | 0.103 | |

[ Japan Lubricating Oil Society ]

Copper Corrosion Test

<JIS-K-2513 Copper Corrosion Test Method for Petroleum Products(Tube Test) >

Test Tube Method: Submerge a polished copper test strip in approximately 30mL of test liquid for the specified time.

Copper Test Strip Material: JIS H3100 - C1100P, C1201P, C1220P

Copper Test Strip Size: approximately 75mm long, 12.5mm wide and 1.5-3.0mm thick

Test Conditions: 100℃×3hour

Test Results: 1a

Corrosion Criteria on Copper Test Strip

| 1 | 2 | 3 | 4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | a | b | c | d | e | a | b | a | b | c |

Power Consumption Test

| Types of Oil | Power Consumption before using SUPER ZOIL(kw) | Power Consumption 90 days after using SUPER ZOIL(kw) | Saved Power(%) |

|---|---|---|---|

| Hydraulic Oil | 1.0358 | 0.8535 | 17.6 |

| 7.7662 | 6.6384 | 14.5 | |

| Lubricating Oil | 0.012 | 0.0096 | 14.3 |

| Gear Oil | 1.3962 | 1.1978 | 14.2 |

| 1.4166 | 1.1974 | 15.5 |

[ Provided by a Major Auto Manufacturer ]

Test Contents

Test Location: A factory line at a major auto manufacturer

Test Method: Add 10% of SUPER ZOIL to lubricant oil, gear oil and hydraulic oil

Measurement Condition: The measurement was conducted for 12 hours a day to compare the power consumption before and after SUPER ZOIL use.

Test Time: 90days